From having gas in our stoves to water in our faucets, steel pipes play a vital role. Likewise, every household in the world depends upon water and gas pipelines for the safe transport of these essentialities in our daily life. But how do these pipes survive for so long amid weather and chemical conditions? It is all about the quality of steel pipes you use. From stainless steel tubing to carbon steel pipes, all have a substantial role in our industry. Because thick pipelines as well as thin wall stainless steel fittings pipes, both are important for you. To understand better, you need to know all about steel pipes first.

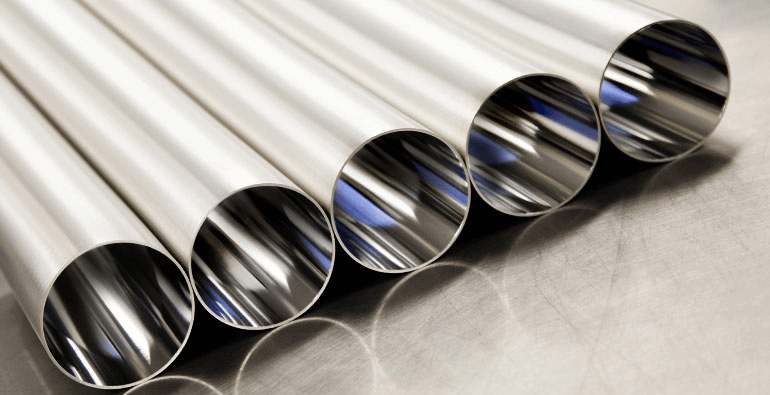

What Are Steel Pipes?

Hollow steel tubes with the function of transporting various types of gases and fluids are steel pipes. When it comes to extracting gas from the ground and also transporting it to millions of locations, these steel pipes play their roles. Moreover, while extracting oil from the ground, the same steel pipes are used. Now you would know how essential this product is. Almost every industry depends upon these steel pipes for manufacturing their products whether it is food, oil, gas, mining, medical, or any other industry, steel pipes are the foundation of them.

Seamless Pipes

When steel billets are passed through a hot furnace to penetrate them from the middle for the formation of hollow tubes, seamless steel pipes are formed. It has no split point like welded pipes, which you will read below. Because of having more thickness, these pipes have better features and higher costs. The reason is their usage in tough environments like oil and gas extraction, underground mining, and nuclear power plants.

Welded Pipes

When large sheets of steel are rolled to make both ends connect via welding, they result in the formation of welded pipes. It is simpler than the first method and also less expensive than the seamless one. Likewise, welded pipes are used for normal conditions, where high temperature and pressure are not required.

Where Are Steel Pipes Used?

If we study deep, these steel pipes are in almost every field of life. Commercial, industrial, and domestic, all are contributed by these steel pipes. To illustrate better, have a look at their general uses.

Mining Industry

Steel pipes are very common in the mining industry for the safe extraction of minerals without letting pipes face any damage. This is because of the high endurance of steel, especially stainless steel. With these features, it can bear tough reactions of minerals in raw form. Furthermore, duplex stainless steel is the type that is used in these industries to survive easily.

Oil And Gas Industry

The highest usage of steel pipes is in the oil and gas industries. Because of heavy-duty requirements, these stainless-steel pipes are a high priority. Its high durability results in smooth transportation of oil and gas, which is the ultimate need of these industries.

There are some highly reactive gases with severe reactions, which need to be transported only via steel pipes. Besides, oil refineries can’t depend upon any other material for piping except steel. 304, 316, and 321 are grades of stainless steel commonly used in this industry.

Nuclear Power Plants

When it comes to nuclear reactors, no one can put a blind eye to the quality of their components in them. Since they contain highly reactive elements like uranium, stainless steel pipes are used to carry steam for the generation of electricity via turbine movement. For this entire process, a durable pipeline is used, where stainless steel is the best option. However, nickel alloys are also used in it but steel is the most general one.

Domestic Applications

Besides industrial usage, it is widely used in the domestic sector. To illustrate, the structure of water and gas supply depends upon steel pipes. Because of their pressure and temperature-resistant features, they can be trusted by households. In addition, these steel pipes are used for railings on stairs and balconies. People use them because of their anti-corrosion features and elegant appearance.

Types Of Steel Pipes

If we describe the types of steel pipes, there are normally four types. However, some of them have similar features with very little difference. To understand it well, check out these main types of it.

Carbon Steel Pipes

The first one is carbon steel pipe, which is the cheapest and the most basic type. Since it has no additional layer, it has limited strength like fine resistance to high temperature and survival for over 50 years. However, it can corrode easily as compared to other types of steel pipes. Many households had this type in the past but now they are being replaced by newer and good quality pipes.

Black Steel Pipes

This type is made up of non-galvanized steel but has an iron oxide coating for rust prevention, which helps it supply gas easily. Though it is better than carbon steel pipe in some ways it can’t withstand water. The reason is the same, which is its non-galvanized form. Moreover, it is widely used in oil and gas industries because of its good compatibility with oil and gas elements.

Galvanized Steel Pipes

Galvanized steel pipes have zinc coating, which saves them from corrosion. Likewise, these pipes are great for water supply in households. However, these galvanized pipes have some limitations, which is that they are not suitable for gas. The reason is the gas reaction will end up with the removal of a galvanized layer.

Stainless Steel Pipes

Here comes the final form of steel pipes, stainless steel. With main components like nickel, chromium, molybdenum, and iron, stainless steel has strong resistance to water, gas, and other environmental factors. Moreover, it contains around 10% chromium, which makes it stainless as compared to the rest of the above types. Stainless steel pipes have a substantial worth in food, oil, gas, agriculture, construction, and chemical industries. With high resistance to high and low temperatures, this type can withstand rough environmental conditions.

Importance Of Steel Pipes

After reading the above details, you might have realized the worth of steel pipes. There are some core features of steel pipes, which help them stand out against other materials of pipes. Have a look at these features below.

Durable And Resilient

These steel pipes can survive centuries. Yes, that’s true. The reason is the quality of allowed in it, which holds them against variability environmental factors. This is why many pipes don’t require any maintenance for many years. As a result, companies rely upon them for the transportation of fuel via underground pipelines.

Corrosion Resistant

Due to their special resistance, they can avoid corrosion for a long period. It is not possible with any other alloy, especially with that low cost. Yes, steel pipes are less expensive than other materials.

Temperature Resistant

Whether it is an arctic or a blazing region. Steel pipes are meant to be used for both. This feature helps the stand tall against every weather condition for years. As a result, users have an unshakable trust in these steel pipes.

Conclusion

All types of steel pipes have their own worth, which proves to be essential in their right usage. Since you have understood much about these pipes, you will not get confused about their types.